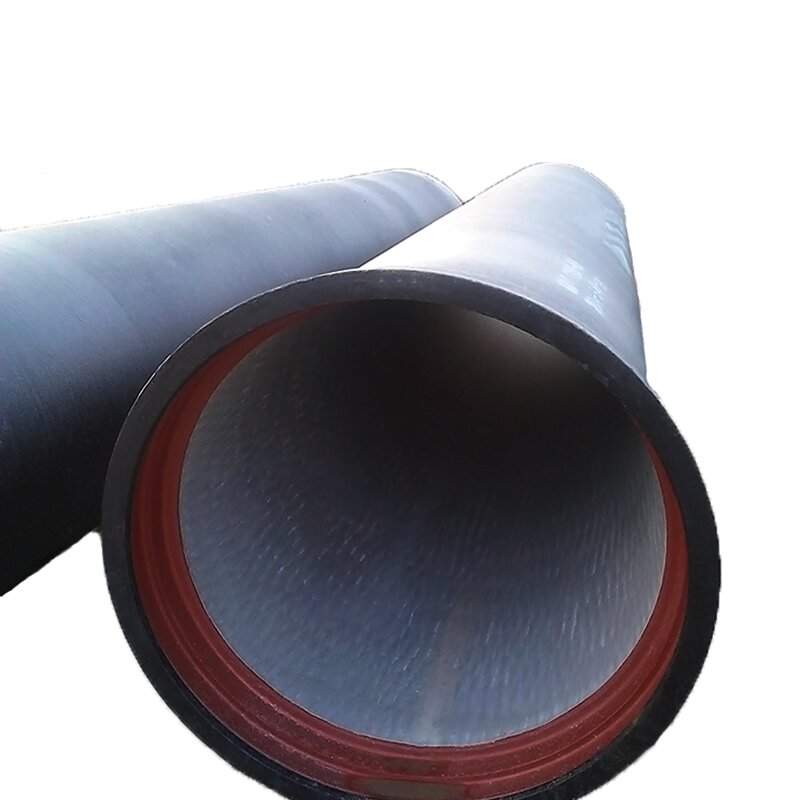

Ductile Iron Pipe

Ductile iron pipe is a conveying pipe forged from iron with nodularizing agent. However, there are very many kinds of cast iron pipes, and ductile iron pipe is only one kind of cast iron pipe. The reason why the finished ductile iron pipe pool has been better improved is the mechanical nature of the material itself. The nature of iron and the performance of steel are well reflected in ductile iron pipe, so ductile iron pipe has the title of "steel instead of iron".

The material of the ductile iron pipe is cast iron. Because the mechanical properties of general cast iron are not high, measures are taken to convert flake graphite in cast iron into spherical graphite, which greatly improves the mechanical properties.

In order to distinguish ordinary cast iron, it is called nodular cast iron.

Ductile cast iron pipe (DCIP): including annealed ductile iron pipe (currently suitable for small and medium diameter pipes), as-cast ductile iron pipe (currently suitable for small and medium diameter pipes).

Ductile iron pipe is the product of modern urban water supply, property fire protection, and gas transportation. However, many customers do not know its advantages and disadvantages. Today I will tell you the importance of galvanizing for ductile iron pipe. After investing huge sums of money and repeated tests on countless materials for many years, we finally found a cheap and high-quality anti-corrosion material that can be applied to conventional situations—zinc.

The pipeline plays an active protective role and forms a stable protective layer. During the contact process with the soil, the metallic zinc gradually transforms into a tight, cohesive, continuous zinc salt layer, and the outer layer of asphalt paint (seals the pores) is as Like thin films, zinc is transformed into insoluble zinc salts rather than soluble zinc hydroxides.

One of the main features of the sprayed zinc layer is the ability to automatically repair the protective layer at the damaged site. In order to solve the corrosion problem of ductile iron pipes to maintain the integrity of the protective layer, zinc ions migrate to the damaged site by sealing the pores (ie bituminous paint coating) to fill the wound and transform into a stable insoluble spray.

The anticorrosion treatment of ductile iron pipes also has the following points: first, asphalt paint coating, asphalt paint coating is used to transport gas pipelines. Preheating the pipe before painting can improve the adhesion of asphalt paint and speed up drying.

The second type is cement mortar lining + special coating. This internal anti-corrosion measure is suitable for pipelines that transport sewage and can improve the corrosion resistance of the lining. The third type is epoxy coal tar pitch coating, which is suitable for both gas pipelines and sewage pipelines. It is a two-component coating, which has high adhesion and a very smooth surface. Epoxy ceramic lining is suitable for sewage pipes and gas pipes, but due to the difficulty of manufacturing process, The cost is high, so there are certain limitations in use.

The last type, the epoxy ceramic lining has high adhesion and finish and is an excellent anti-corrosion coating. Aluminate cement coating and sulphate cement coating, these two special cement coatings are suitable for the internal anti-corrosion of ductile iron pipes used in sewage pipelines, and improve the ability to resist the erosion of acid and alkali components in sewage.

Packing of Ductile iron pipe